Manufacturers and industrialists in almost every sector have a drastic opportunity at hand where they can not only monitor but in addition, automate a handful of complex processes involved in manufacturing. Even though there are systems which can track progress in the plant, the industrial IoT (IIoT) technology provides far more intricate details to the managers.

According to a research by Business Insider, global manufacturers will invest $70 billion in IoT solutions in 2020. That’s up from $29 billion from 2015.

The main focus of this blog is to help educate executives in the manufacturing industry about the possible use cases of Industrial IoT and ways of leveraging it.

Digital/Connected Factory:

IoT enabled machinery can transmit operational information to the partners such as original equipment manufacturers to field engineers. This will give operation managers and factory heads an opportunity to remotely manage the factory units and take full advantage of process automation and optimization.

Along with this, a digitally connected unit will develop a much better line of commands and help identify key result areas (KRAs) for managers.

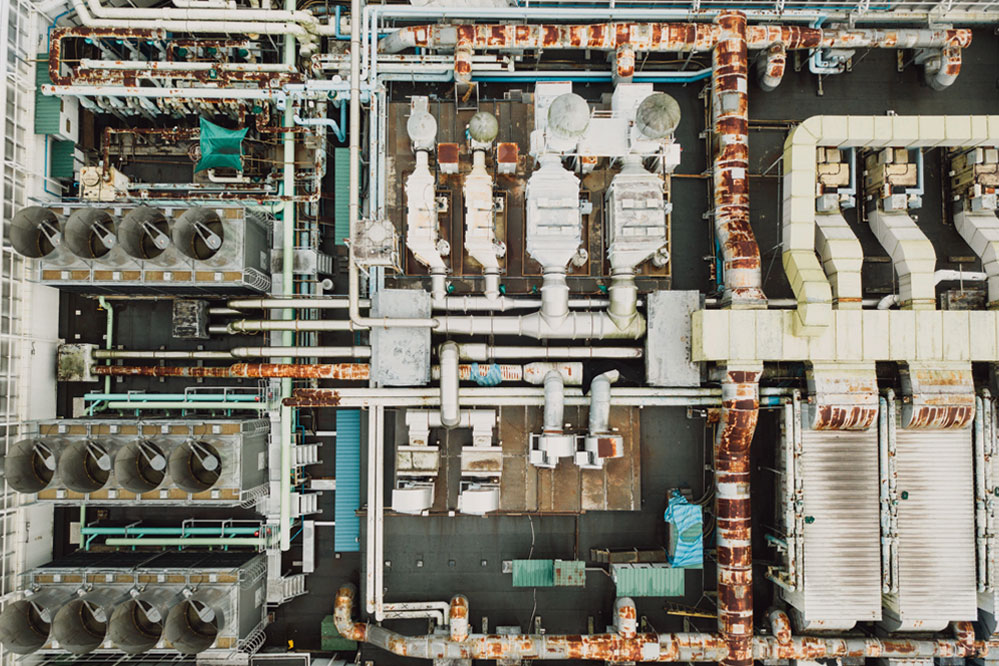

Facility Management:

The use of IoT sensors in manufacturing equipment enables condition-based maintenance alerts. There are an array of critical machine tools that are designed to function within specific temperature and vibration ranges.

IoT Sensors can actively monitor machines and send an alert when the equipment deviates from its prescribed parameters. By making sure the prescribed working environment for machinery, manufacturers can conserve energy, reduce costs, help get rid of machine downtime and increase operational efficiency.

Production Flow Monitoring:

IoT in manufacturing can enable the monitoring of production lines starting from the refining process down to the packaging of final products. This complete monitoring of the process in (near) real-time provides scope to recommended adjustments in operations for better management of operational cost. Furthermore, the close monitoring highlights lags in production, as a result getting rid of wastes and unnecessary work in progress inventory.

Inventory Management:

IoT applications allow for the monitoring of events across a supply chain. Using these systems, the inventory is tracked and traced worldwide on a line-item level and the users are alerted of any major deviations from the plans.

This provides cross-channel visibility into inventories and managers are provided with realistic readings of the available material, work in progress and estimated the arrival time of new materials. In summary, this optimizes supply and helps lower shared costs in the value chain.

Quality Control:

IoT sensors gather aggregate product data and other third-party syndicated data from an assortment of stages of a product cycle. This data relates to the composition of raw materials used, temperature and working environment, wastes, the impact of transportation etc. on the final products.

Moreover, if used in the final product, the IoT device can help provide data about the customer sentiments on using the product. All of these inputs can later be analyzed to identify and correct quality issues.

Logistics and Supply Chain Optimization:

The Industrial IoT (IIoT) can aid in providing access to real-time supply chain information by tracking materials, equipment, and products as they easily move through the supply chain. Effective reporting gives manufacturers a chance to collect and feed delivery information into ERP, PLM and other systems.

By connecting plants to suppliers, all the parties concerned with the supply chain can trace interdependencies, material flow and manufacturing cycle times. This data will help manufacturers predict issues, help lower inventory and potentially reduces capital requirements.