If you were to walk into a power plant 30 years ago, you would find the operator operating a intricate control station of manually operated gauges and levers.

Thanks to recent advances in optimization technology, factories built within the last 20 years boast a very different scenario — an operator managing a room full of computers.

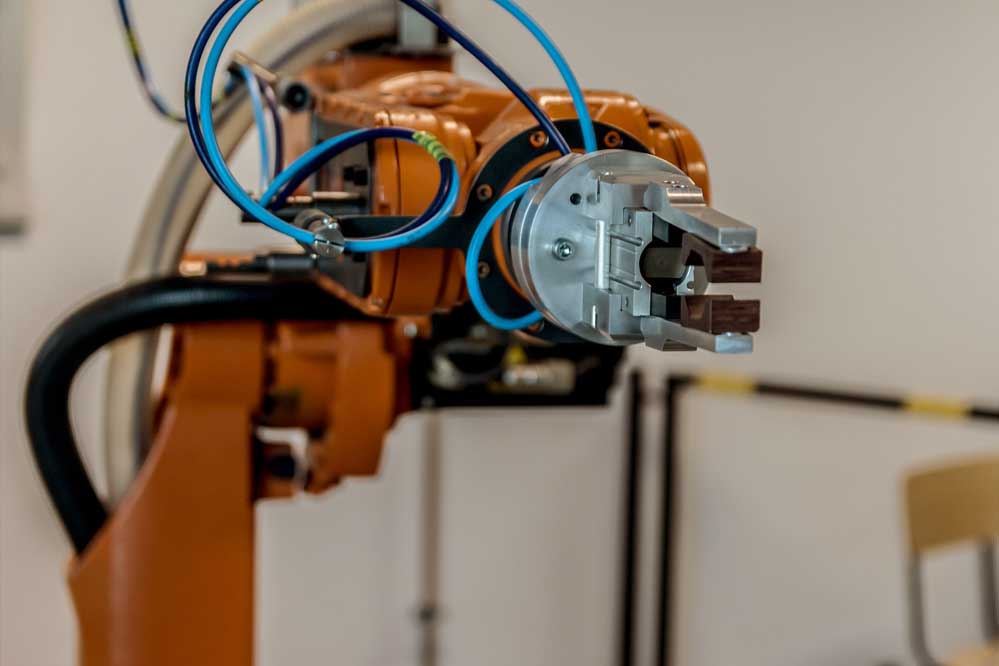

We are entering the Fourth Industrial Revolution, and it looks very different from the previous three. This Revolution addresses the rapid indoctrination of cyber-physical systems referred to as the Internet of Things.

The drastic significance of IOT extends beyond streamlined processes; it signifies a job, lifestyle, and cultural change in how we approach business and production.

The Driving Forces for Optimization Technology

Power Plants are reaping the benefits of the digital age. But, it is not the increasing accessibility to technology alone that’s driving the change.

Here are just three of the driving forces for change in the market:

The advance of renewable generation. Traditional electricity grids must adapt to support the growing demand for renewable energy.

Global fuel expenses. As the worldwide price of fuel rises and fluctuates, plants face the challenge of conserving fuel while maximizing energy output.

The effects of environmental concerns and legislation. A spotlight on the environmental effects of fossil-fuel operations has resulted in increasingly strict emission control legislation. Coal-fired plants risk closing down if they cannot comply with the new restrictions as well as more modern facilities with advanced plant automation systems.

Power plants that are embracing a digital landscape are seeing increased employee safety, process efficiency, and a higher return on investment. The solution to their achievement in plant automation? It’s the Internet of Things (IOT).

What Is IOT and How Are Power Plants With It?

The Industrial Internet of Things (IIOT) connects machines and devices via the cloud. It’s the connection between a power plant’s hardware and software. It enables quick user access to all stages of the process. The footprint for a basic IIOT system is made up of four components:

Hardware — A device that transfers accumulated data to the cloud.

Connectivity — This can be as simple as an Ethernet or wi-fi connection.

Software – A program that translates the hardware data points into a user-friendly information.

A User Interface – Now that the information is displayed, an application is necessary to allow the user to analyze the situation and adjust accordingly.

An IOT system improves operational efficiency. Where plant automation before consisted of several optimized operations (from the combustion process to the emission control systems) working independently of one another, IOT centralizes all of the automation.

Plant operators can now make high-level decisions that affect all parts of the operation accordingly. In reacting quickly to electricity demands and eliminating unnecessary energy expenditure, plants are seeing tangible cost savings.

Until recently, power plants operated with a steady, unwavering output. Today’s needs require plants to operate with varying levels of on-demand flexibility. Optimized systems can analyze historical data to make preventative maintenance decisions that decrease the stress this can cause facilities.

The automation system sets an operating benchmark for process parts and components. It then self-monitors and alerts teams when conditions stray outside of the acceptable parameters. Performing maintenance on warning signs before they become failures drastically reduces outages.

IOT and Improved Worker Safety

Gas leaks, fires, and explosions are a valid concern for workers who spend their days in power plants. IOT allows power plants to prioritize employee safety both by streamlining general operations and creating an open, fast channel of communication between employees and operators.

Employees equipped with personal gas detection devices can send immediate notification to emergency responders with specific details of the episode. Location trackers keep emergency responders from wasting time and jeopardizing the safety of all parties. Information is instantaneously relayed through email, alarms, and even text messages.

IOT In Summary

Demands for power plant automation are not going away. Plants are harnessing the Internet of Things to operate at a high-functioning pace and efficiency never seen before.

By 2022, estimates say there will be 31 billion connected devices globally. Experts also predict by this date, more than half of major new businesses will operate through IOT.

The “Connected Worker” is on track to becoming an industry standard for safety. Connectivity opens the door for streamlined processes, predictive maintenance, and a more profitable bottom line. The Internet of Things is the future for plant automation