At this point, designing machines for the development of the Industrial Internet of Things (IIoT) are one of the main assets for engineers that are in charge of bringing together the digital and physical world on the shop floor. This requires engineers to incorporate a wider range of components and subsystems into the machinery.

Designers must also be able to deal with more complex issues and accept the complexity of the design process. Engineers will need to adapt to new methods and tools to succeed.

Things are getting more complicated

Take a good look at the IIoT reveals dynamic forces in the new industrial landscape: it is a reflection of the forces at work. While managers need to connect machinery to plant operations systems, individual production lines, and customers, users want smarter interfaces and greater functionality.

Vendors offer an incredible array of technologies and devices to integrate these features into machinery. Although this wealth of options can offer designers many advantages, it can also be a burden.

The speed of technological advancement is so accelerated that it is becoming difficult to keep up with the latest technologies and their new uses.

Distributors are a key part of our business. However, selling things is not the same as integrating them and making them work.

Engineers need to know how the technology will enable the management and use of data while evaluating their choices. The IIoT will produce a lot of data from the next generation of industrial machines.

That is to say, designers need to decide what to do with all the data.

The availability of data and pervasive connectivity have opened the doors to great advancements while designing machines. However, this also means that designers must face new challenges. One of these challenges is to ensure security.

In the past, machines might have only had limited communication capabilities. The addition of network communications allows designers to transform huge data into IIoT benefits, but, it also makes operations and plant data vulnerable to cyberattacks. Design teams are now using industrial security assessments as well as a variety of tools to assist.

In other words, these factors all have influenced machine design, and the IIoT makes the process even more dynamic. As a result, the traditional serial design process has been replaced by the design phase.

Generative Designing Machines with AI

The requirements set forth by the IIoT Engineers have had to develop new design methods that transcend traditional methods because of market-driven space, time, and cost constraints. Generative design is a way to mimic nature’s evolution process using artificial intelligence.

Engineers can use this approach to interact with algorithms to create and evaluate hundreds upon thousands of possible designs. The engineer must first enter the goals and constraints of the project into the software. These parameters can include performance and spatial requirements, manufacturing methods, cost constraints, and materials.

The software generates many design options quickly through an iterative process. It explores all possible combinations and learns what works from each iteration.

Recent use cases show that generative design can reduce part mass by up to 30% in traditional manufacturing and as high as 70% using additive manufacturing. This approach guarantees to enable innovation and contribute solutions to difficult obstacles that are resource-exhaustive using conventional methods.

Generative design uses artificial intelligence to enable designers to quickly generate design alternatives and explore every possible solution. The algorithms learn from each iteration what works and what doesn’t.

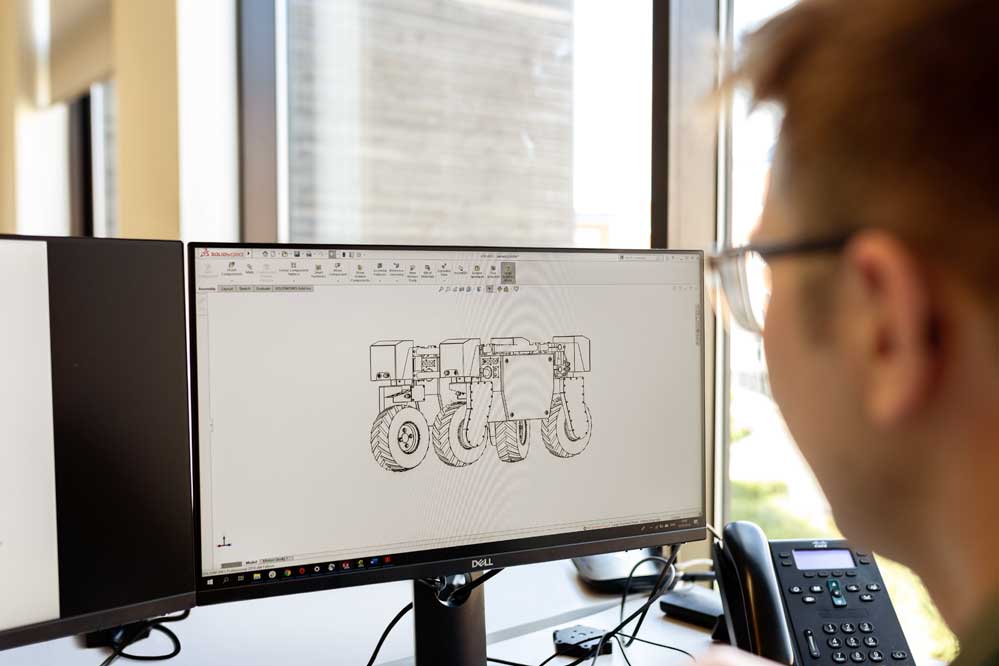

Designing machines is no longer limited to mechanical CAD.

Simulating and modeling go hand-in-hand. More engineers working in mechanical engineering are adopting generative design. This allows them to build their model by optimizing topology and then iterating on the simulation model.

The Very Best of Both Worlds

Another popular method is design modularization. This combination mixes the benefits of standardization and customization.

This is how design teams break down a system into discrete modular modules to use multiple systems. Engineers use industry-standard modular interfaces to ensure interoperability.

This approach is driven by seemingly mutually exclusive needs. Machines for industrial facilities must be able to meet the specific requirements of their applications. This includes size, speed, and other specialized features.

Machinery companies use modular strategies to satisfy these needs. They make sure that each functional area can be customized and streamline the manufacturing process by using similar designs.

A second issue is a constant need to modify industrial machinery. This is similar to customization demands. Few operations can remain the same for decades or more in this industry.

The demands are always changing and the most competitive industrial facilities can capitalize on them before the competition. This level of flexibility can be provided by engineers through design modularization.

Learn more about designing machines! Contact us!